Farm Residue to Fashion: Our Journey with AltMat

How often do we think about the raw materials used in our garments? Raw material production and their processing contribute to up to approximately 2/3rd of the GHG impact of the fashion industry. Most brands have set ambitious targets to integrate sustainable, low-impact materials into their supply chain and make them accessible to consumers. Therefore, it is essential to replace conventional materials with next-generation material alternatives. A report by the Boston Consulting Group stated that the demand for low-impact raw materials could exceed supply by as much as 133 million tons by 2030.

Alternative materials are available, but most exist in the early R&D stage. It is essential for suppliers to partner with innovators to provide them with supply chain integration and unique insights to scale to an industrial level. Read below to learn more about how Shahi Alternative materials are available, but most exist in the early R&D stage. It is essential for suppliers to partner with innovators to provide them with supply chain integration and unique insights to scale to an industrial level. Read below to learn more about how Shahi and AltMat worked together to scale fabrics made from agricultural residue. and AltMat worked together to scale fabrics made from agricultural residue.

About AltMat

The fashion industry and biodiversity are intrinsically linked as we rely on a naturally limited supply of resources to grow its raw material — natural fibers. The fashion industry is in search of new raw materials. In our quest to find lower-impact next-generation materials, in 2021, Shahi came across AltMat in one of the innovation showcases. AltMat is an Alternative Materials Science company that converts agricultural residues into high-performing natural materials called Altag. Using materials science and sustainable proprietary processes, they can transform biomass of certain food, medicinal, and industrial crops into natural fibers for the fashion industry.

The Impact

Shahi believes in the power of AltMat to bring exponential positive impact on the industry. One, as a solution to the industry’s and brand’s search for alternatives and, in parallel, a pathway for millions of farmers who burn their crop residues and set off dangerous emissions levels for want of better options. Additionally, we can divert several resources, such as water and energy used to grow raw materials, to alternate uses.

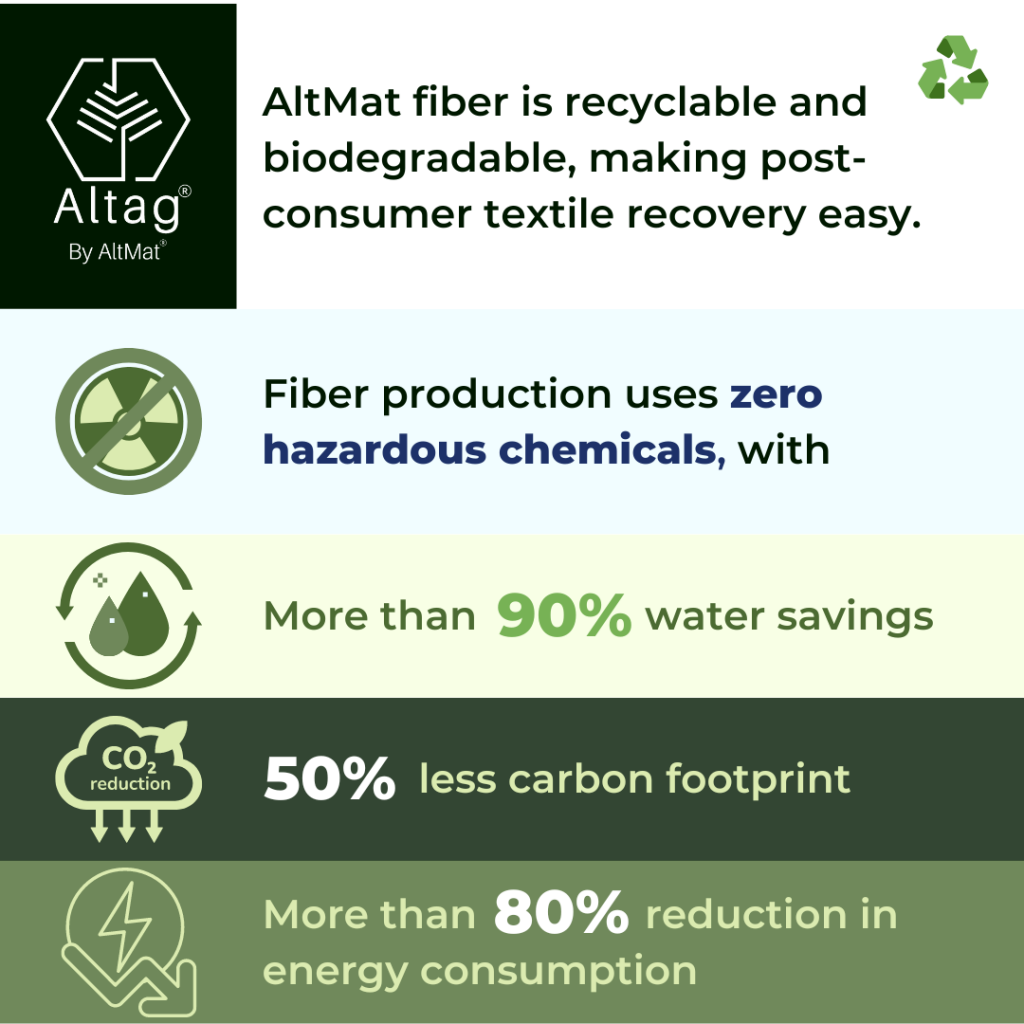

The agricultural residue is converted into fiber using a series of proprietary traditional, microbial, chemical, and mechanical methods to retain the natural structure of the fiber. AltMat has carefully built the processing methodology to ensure sustainable production.

Fiber production uses zero hazardous chemicals, with more than 90% water savings, 50% less carbon footprint, and more than 80% reduction in energy consumption. AltMat fiber is recyclable and biodegradable, making post-consumer textile recovery easy.

The Collaboration

As a vertically integrated manufacturer, Shahi is uniquely positioned to integrate Altag into the supply chain for scaling it with our strategic and innovative brand partners. To accelerate the market adoption of Altag, Shahi and AltMat have signed a Value Chain Agreement that underscores the importance of partnerships grounded in the ethos of equitable purchasing practices and sustainable transformation. As a value chain partner, Shahi has priority access to the Altag yarns and co-develops fabrics with our global chain of innovative customers.

“Scaling sustainable alternatives like AltMat isn’t easy, but the journey is where the true impact lies. It is about shared learning, open collaboration, and a shared mission to rewrite the future of fashion. Suppliers like Shahi, working with innovators directly, can share their feedback to help refine the solution for industrial scale. AltMat is an example of how a successful partnership can build an enabling ecosystem to scale.”

— Gauri Sharma, Assistant General Manager, Communications & Sustainability Innovations, Shahi Exports

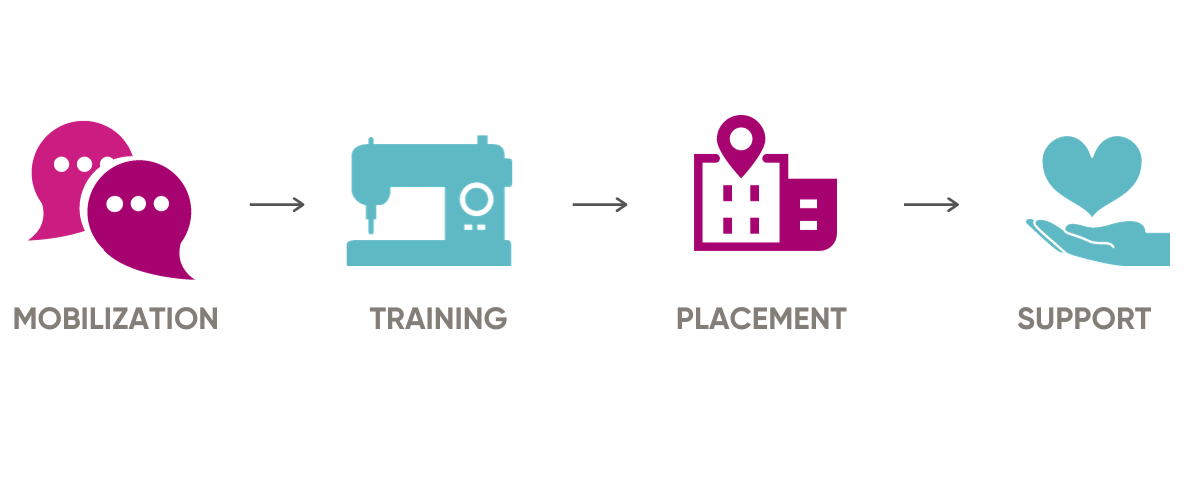

The R&D Journey: Scout, Pilot, Scale, and Support

Scout

The agreement and collaborative scaling of AltMat to the industry scale is the culmination of our numerous pilots for woven and knitted fabric made from agricultural residue. During an innovation showcase, we were introduced to AltMat in September 2021 by CAIF under their Project Accelerating Circular Economy (ACE). Post the showcase, we held several discussions between our technical teams and AltMat to understand the technology, implementation feasibility, and traceability guidelines.

Pilot

In December 2021, we initiated our first woven pilot project with AltMat with two quality compositions. We undertook four pilots over two years to experiment with different structures, compositions, counts, and designs of the fabric. Working with innovators, we are able to provide feedback from the industry perspective and technical know-how that helps innovators such as AltMat to incorporate them, accelerating the process for scale up.

The learnings from each pilot helped us explore the versatility of Altag with a myriad of dyeing techniques and finishes. Fabrics made with Altag have a hand feel similar to natural cellulosic fabrics. The fabric retains the natural structure, which changes over time. That is the beauty of the Altag fabric.

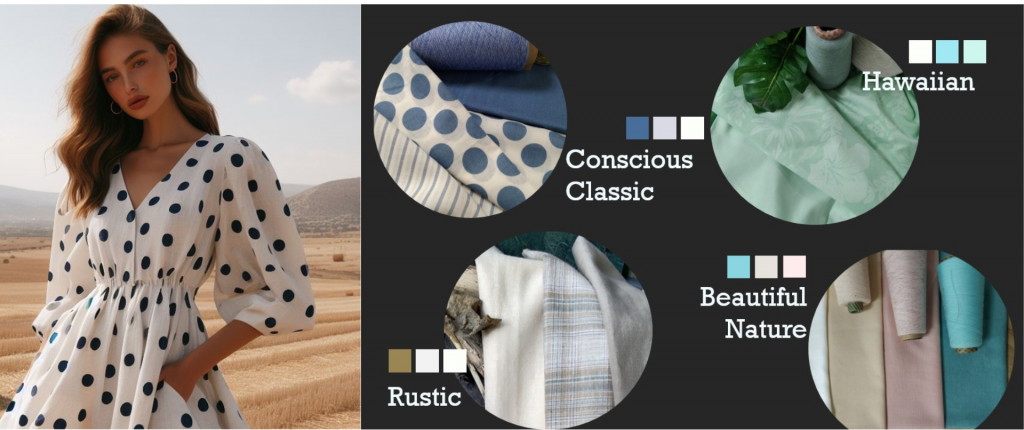

The learnings from the pilot resulted in a synchronized swatch book with over 10 different woven fabrics made with Altag spread across four collections:

The collection was made in active collaboration with a diverse team at Shahi, ranging from the technical mill team, Fabric Innovations, and R&D to the Marketing team.

Scale

After ensuring the industry quality standards, the woven collection is ready to be scaled up to the industry level. Shahi and AltMat, in collaboration with Fashion for Good, recently held a brand engagement session attended by over 15 brands. Being a competitive space, the brand engagement session is a testament to how the industry wants to collaborate with each other to achieve the common goal of making low-impact materials available to the typical consumer at scale. Currently, we have one bulk order in the pipeline from our customers for the AltMat collection. Shahi will be the first manufacturer globally to scale Altag.

Support

But the journey continues. Together with AltMat, we continuously work on research and development to produce knitted fabric using agricultural residue. Shahi is the first supplier to pilot Altag for knitted fabric in India, and we have completed two pilot projects to date. The fabric hand-feel and processing have improved with each pilot and new insights. The Value Chain Agreement signifies our commitment to support AltMat in scaling and integrating them to the larger supply chain.

“Both AltMat and Shahi are prepared with the infrastructure and learning curves required to scale a new natural fiber like Altag. We are excited to announce that the Shahi and AltMat value chain partnership milestone brings this possibility of scale to life.”

— Shikha, Founder, AltMat

Collaboration for the future

With each pilot, each experiment, and each swatch of Altag fabric, we’re paving the way for a cleaner, greener industry, one stitch at a time. With our fabrics made with AltMat, we are actively looking for brand partners to integrate the next-generation material into their supply chains. With each woven and knitted fabric, we’re rewriting the narrative – one where farmers are empowered, resources are conserved, and style goes hand-in-hand with sustainability. Join us in stitching a future where fashion thrives alongside our planet.

For more information, please contact od@shahi.co.in