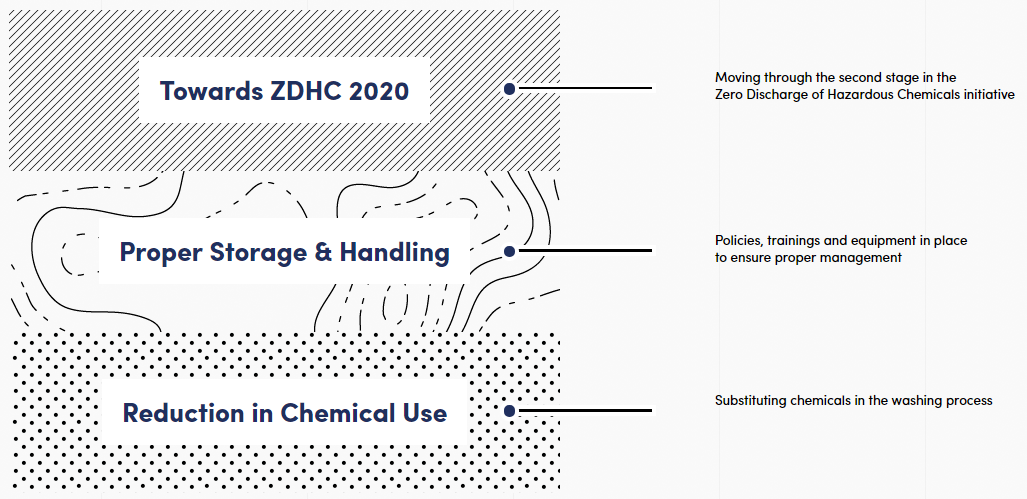

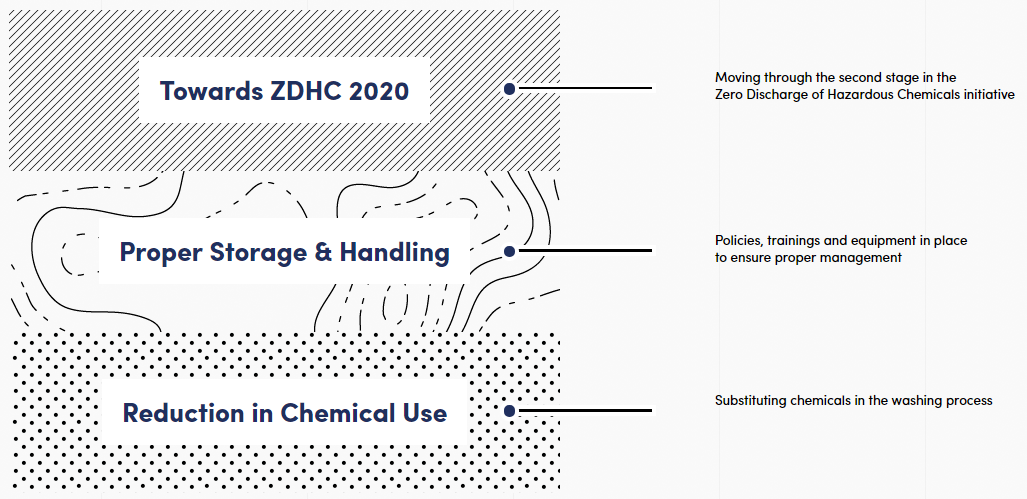

Chemical Management & Safety

We prioritize chemical safety and sustainability. 100% of the dyes and auxiliaries used in our production processes adhere to the stringent ZDHC MRSL standards. Since 2011, we have led the way in eliminating hazardous chemicals, becoming one of the first to pass Zero Discharge of Hazardous Chemicals (ZDHC) audits in 2012-13.

Sustainable Chemicals

Embracing cutting-edge and innovative solutions allows us to significantly reduce our environmental footprint while maintaining high-quality standards in our products. One such example is our wovens mill, which has transitioned 30% of its dyeing process to a salt-free method, saving 300 tons of salt and subsequent steam.

Responsible Sourcing and Traceability

We ensure responsible sourcing by focusing on transparency, ethical practices, and sustainability.

Through initiatives like Trakwel, we digitize operations to enhance efficiency, accuracy, and resource optimization, driving a sustainable and transparent supply chain.

Sustainably sourced materials

We are committed to increasing this share through strong partnerships, which help strengthen the supply chain and drive progress toward a more sustainable future. Our materials include BCI Cotton, Organic Cotton, Regenerative Cotton, Sustainable Viscose, and Recycled Polyester.

Read more about how we turned Farm Residue to Fashion: Our Journey with AltMat.

100% renewable electricity by FY 2026-27

Renewable Electricity

We have set up solar power plants and windmills in Karnataka with total capacities of 92.5 MW.

These generate 70% of Shahi’s total electrical energy consumption. Know more about Shahi’s journey to 100% renewable energy.

Carbon-Mitigation

We have successfully mitigated over 600,000 metric tons of GHG equivalent emissions.

50% carbon neutrality by FY 2026-27

In all garmenting units and 1 mill

Energy & Emissions Intensity

We’ve implemented various initiatives, including natural lighting, motion sensors, improved ventilation systems, tree planting, and shifting from coal to cleaner fuels like agro-waste and solar.

Train 100% of supervisors in STITCH by FY 2024-25

New Goal: To train 100% of Supervisors and Incharges in STITCH 2.0 by FY 2027-28.

STITCH: Supervisors’ Transformation Into Change Holders

A 6-month soft-skills and leadership program that imparts technical training to aspiring and working managers on leading their teams, fostering a positive workplace culture, and driving operational efficiency.

We’re transforming STITCH into a comprehensive learning system that aligns with the 70/20/10 learning principle. By focusing on self-directed learning, peer collaboration, and formal training, we aim to enhance organizational effectiveness at all levels.

PULSE: Promoting Upcoming Leadership at Shahi Exports

An 8-month immersive curriculum in leadership through personal and interpersonal growth.

To enroll 500 leaders PULSE by FY 2025-26

New Goal: To enroll 650 leaders in PULSE by FY 2025-26

Women Leadership on the Shopfloor

We believe in the power of diversity and inclusion. By increasing the representation of women in leadership roles, we’re creating a more balanced and productive workplace. Our targeted training and development programs have led to a significant increase in female supervisors.

A program is designed to promote gender equality by empowering women to take on leadership roles. Through targeted training in technical and behavioral skills, we equip women with the tools they need to excel.

By implementing this program in two of our factories in Faridabad, Haryana, we’ve already trained 35 women to advance their careers. We’re committed to expanding EWASE to more units and increasing female representation in leadership positions.

To implement in all units of the Knits Division and Men, Bottoms, and Denim Division by FY 2025-26

An upskilling program designed to elevate the work environment by promoting holistic skills in candidates chosen to become Captains. Candidates undergo comprehensive training to manage sewing lines.

Captains are active in our lines

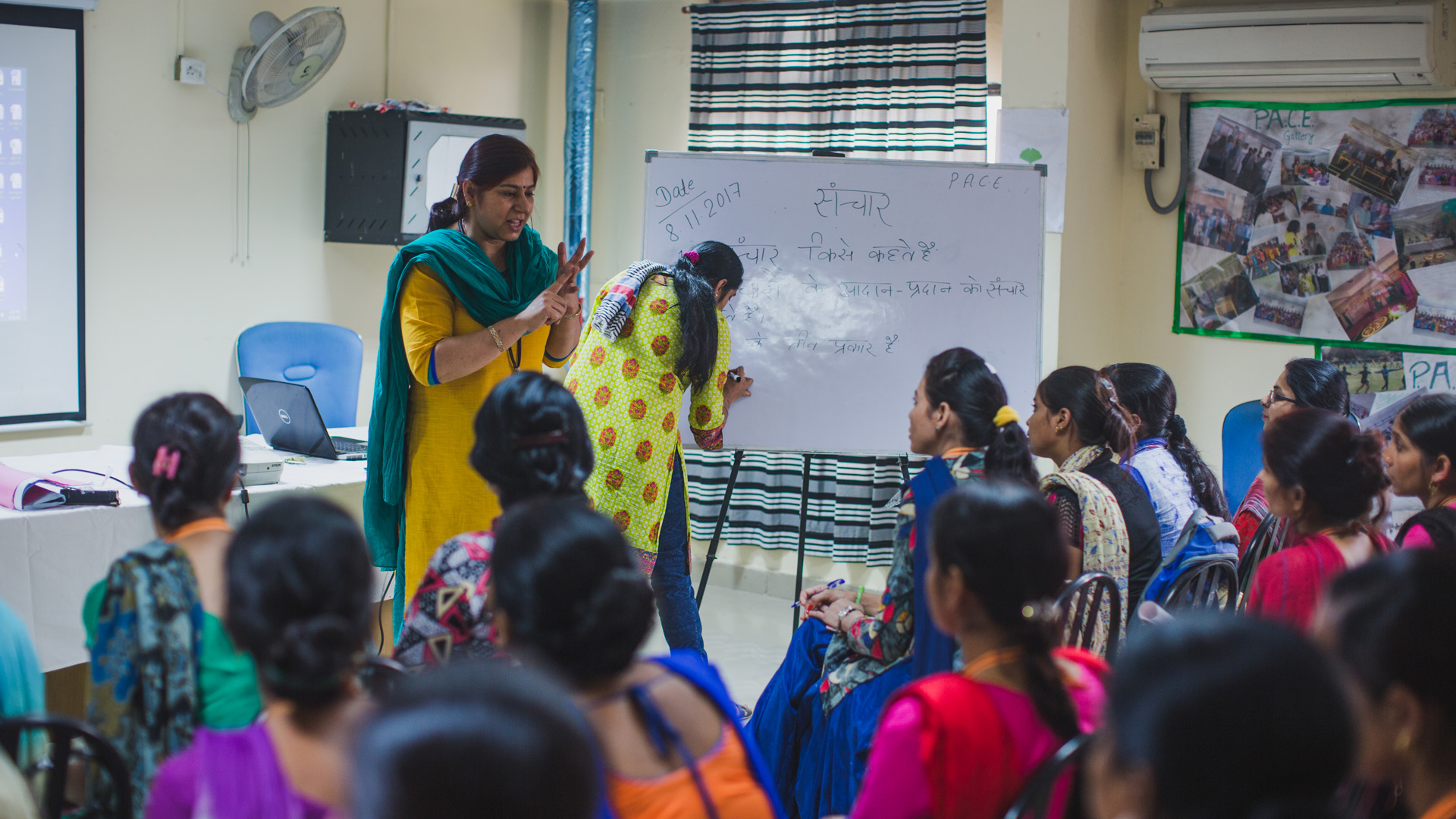

Gap Inc. P.A.C.E.

A comprehensive life skills training crafted for female garment workers, encompassing communication, time, stress management, legal awareness, execution excellence, and more.

The Gap Inc. P.A.C.E. program is now RISE: Reimagining Industry to Support Equality, RISE brings together the four largest women’s empowerment programs in the apparel industry—from BSR’s HERproject, Gap Inc. P.A.C.E, CARE International, and Better Work—to build from proven approaches, scale impact and improve efficiency.

Train 90,000 women in Gap Inc. P.A.C.E. by FY 2024-25

Prioritizing Employee Safety at the Workplace

The Robust Occupational Health and Safety Management (OHSM) system, which adheres to national and international standards, helps ensure employee safety and well-being. Our continuous investment in infrastructure improvements further strengthens our commitment to safety.

Training and Awareness

We conduct extensive safety training, health camps, and awareness sessions to empower our workforce with the knowledge necessary to minimize risks. By raising awareness among our employees, we reduce the likelihood of workplace fatalities.

Employee Health

We have established fully equipped medical centers within all our facilities, with skilled medical teams comprising nurses and doctors to address primary injuries and provide direct medical care. Furthermore, our employees are provided with health insurance, and workers benefit from medical coverage under the Employees’ State Insurance (ESI) scheme.

Pre & Post-Natal Care, and Creche Facilities

We understand the challenges associated with balancing professional responsibilities and parenting duties. Our crèche care has been crafted to offer a secure and nurturing environment for the children of our employees aged below six years. We ensure that the crèche meets the highest hygiene and child development standards.

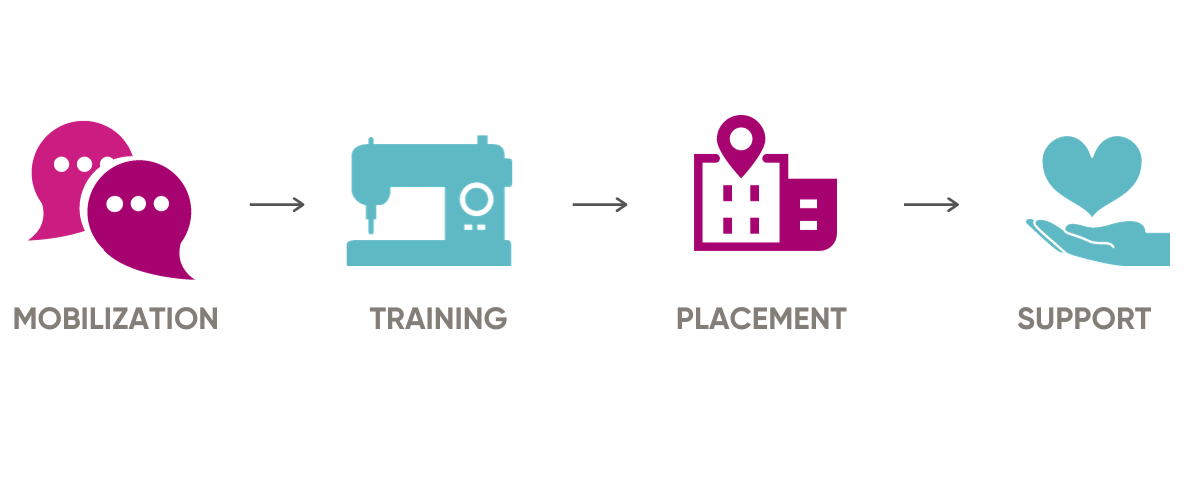

Skills for Employment

Skill Development is a potent instrument for personal and societal advancement. Since 2013, we have been a project implementation partner for the Government of India, offering training programs to underprivileged youth and women.

Skill 65,000 women by FY 2024-25

Training Centers

States

Cover 100% of our factories by FY 2024-25

Social and Labour Convergence Project (SLCP)

With 90% of our factories under this initiative, we’ve saved over 6,912 human hours of audit time and established a unified assessment framework.

Read more about SLCP here.

Enabling Worker Voice

Worker voice is indispensable at Shahi. The key drivers of effective worker voice are:

We are building our ability to listen through various channels and enabling workers to utilize channels transparently and witness the transformational journey that their participation takes.

To achieve 100% accessibility by FY 2024-25

We achieved our goal to scale Inache ahead of time. Our renewed focus is on driving quality and timely resolution.

We leveraged the power of lean and low-tech solutions in collaboration with Good Business Lab (GBL) through their digital, two-way, multilingual, and anonymous communication tool— Inache.

Our pilot with the tool showed a:

Train 100% of our workforce in the first round of BSafe by FY 2025-26

New Goal: Train 100% of our workforce in the first round of BSafe V2 GRM Training by FY 2027-28.

BSafe is a comprehensive awareness program designed to empower our employees. The initiative was developed in collaboration with A&F, Kshitij, and vetted by the Garment Labor Union. In FY 2023-24, we achieved our goal of training all workers in BSafe ahead of time.

To address the emerging needs of our workers, BSafe has been updated to include the following:

→ Recognizing and preventing gender-based violence and harassment

→ Attention to mental health and resources for suicide prevention

→ Understanding cybercrime and its prevention

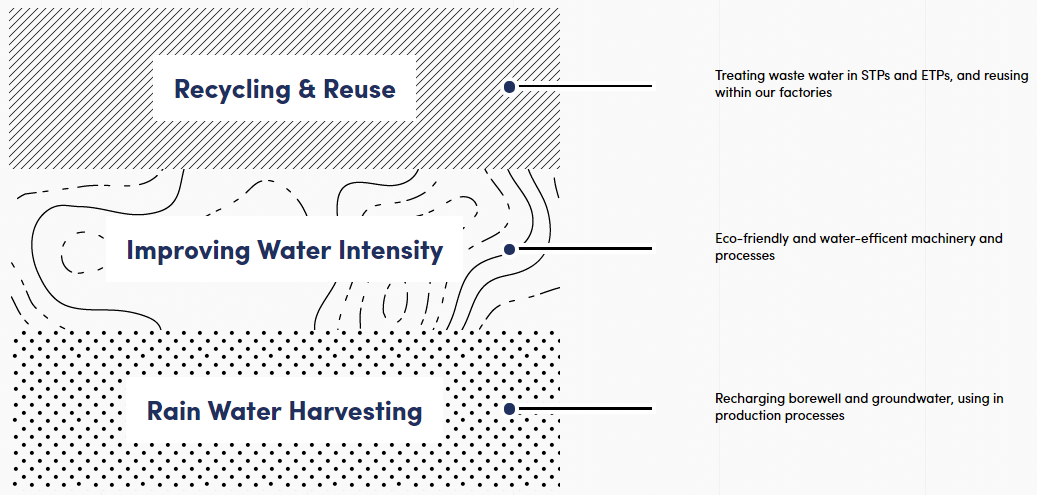

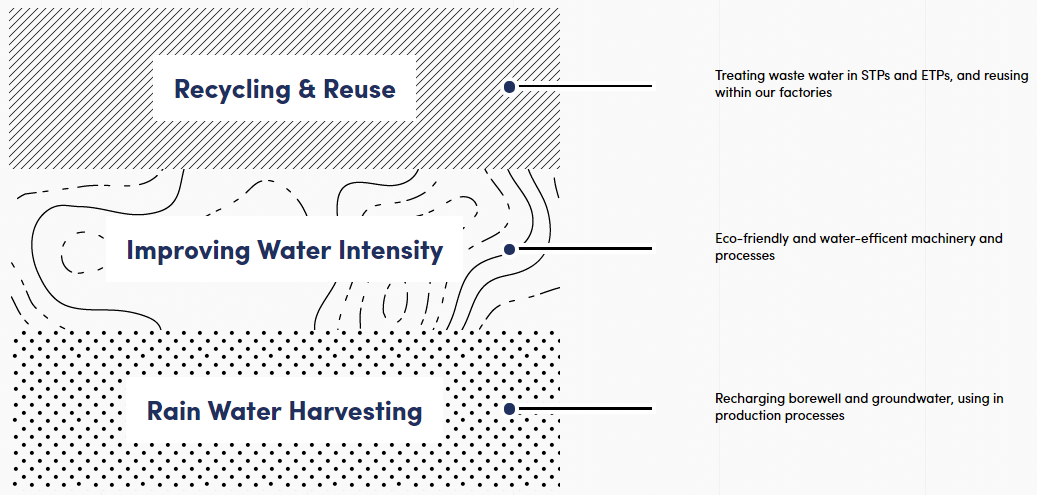

Water Intensity

We are researching, developing, and introducing new technologies to become more water efficient and reduce consumption. Some of our recent initiatives include:

→ Waterless washing technologies such as eFlow and Ozone.

→ Using efficient wash-off chemicals.

→ Recovering condensate water from boilers and dryers.

→ Using Reverse Osmosis (RO) reject for screen and drum washing.

→ Installing aerators at water taps enables up to 20% water savings.

Achieve 85% and 75% recycled water by FY 2024-25, in our garmenting units and mills respectively.

Water Recycling

Our commitment has been to consistently decrease our reliance on freshwater by implementing state-of-the-art effluent and sewage treatment technologies in our pursuit of self-sufficiency.

→ Advanced Effluent Treatment Plants (ETPs) are highly efficient wastewater treatment, enabling water recovery to be reused in our production processes.

→ Reused Domestic effluent (sewage) is also treated through Sewage Treatment Plants (STPs) and in washrooms for ash quenching, horticulture, and dust control.

→ Most of our wet processing units use treated water, helping the facilities achieve Zero Liquid Discharge (ZLD).

Digital Sampling

Digital sampling improves efficiency and resource optimization, supporting eco-friendly practices. This practice fosters seamless collaboration and drives innovation.

Upcycling and Segregation

We prioritize waste reduction and recycling. By upcycling fabric scraps and segregating waste, we maximize resource efficiency. We also partner with recyclers to ensure that non-hazardous waste is properly disposed of. Hazardous waste is safely disposed of through specialized management systems

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

Shahi is a lovely organization to work — professionally driven, wonderful work culture, respect for human values, and strong CSR initiatives.

Water Intensity:

We are researching, developing, and introducing new technologies to become more water efficient and reduce consumption. Some of our recent initiatives include:

Achieve 85% and 75% recycled water by 2024, respectively.

Water Recycling:

Our ongoing commitment has been to consistently decrease our reliance on freshwater by implementing state-of-the-art effluent and sewage treatment technologies in our pursuit of self-sufficiency through:

Read about our water optimization measures in Denim washing and finishing.

Zero Discharge of Hazardous Chemicals (ZDHC):

We have been active contributors to ZDHC since its inception in 2011 and follow the regularly updated AFIRM/AAFA RSL. Our facilities were the first in India to be ZDHC audited by two brands and a third party in 2012-13. We have also developed a single-window chemical purchase procedure to prevent the entry of restricted (priority) chemicals in our operations.

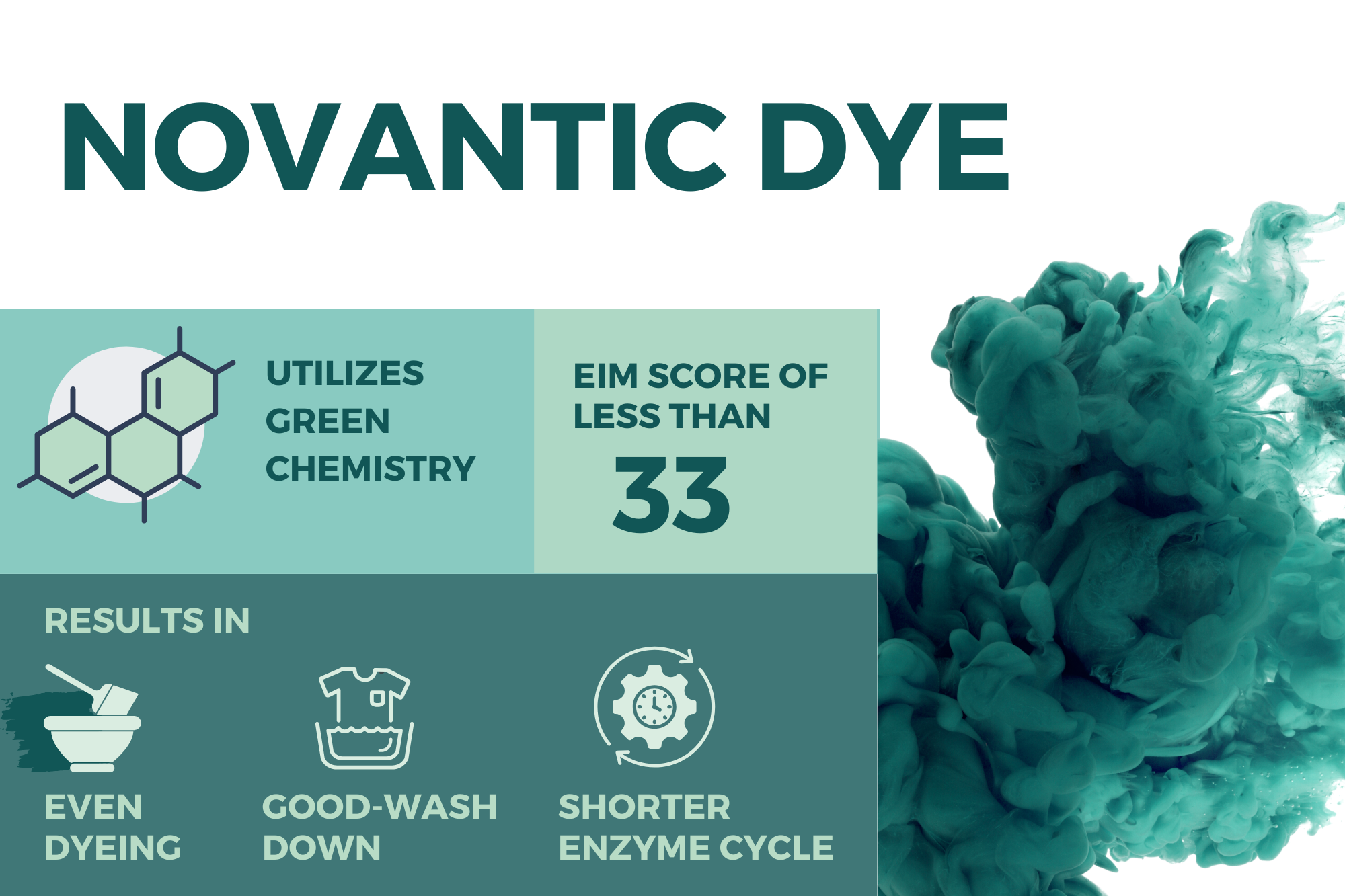

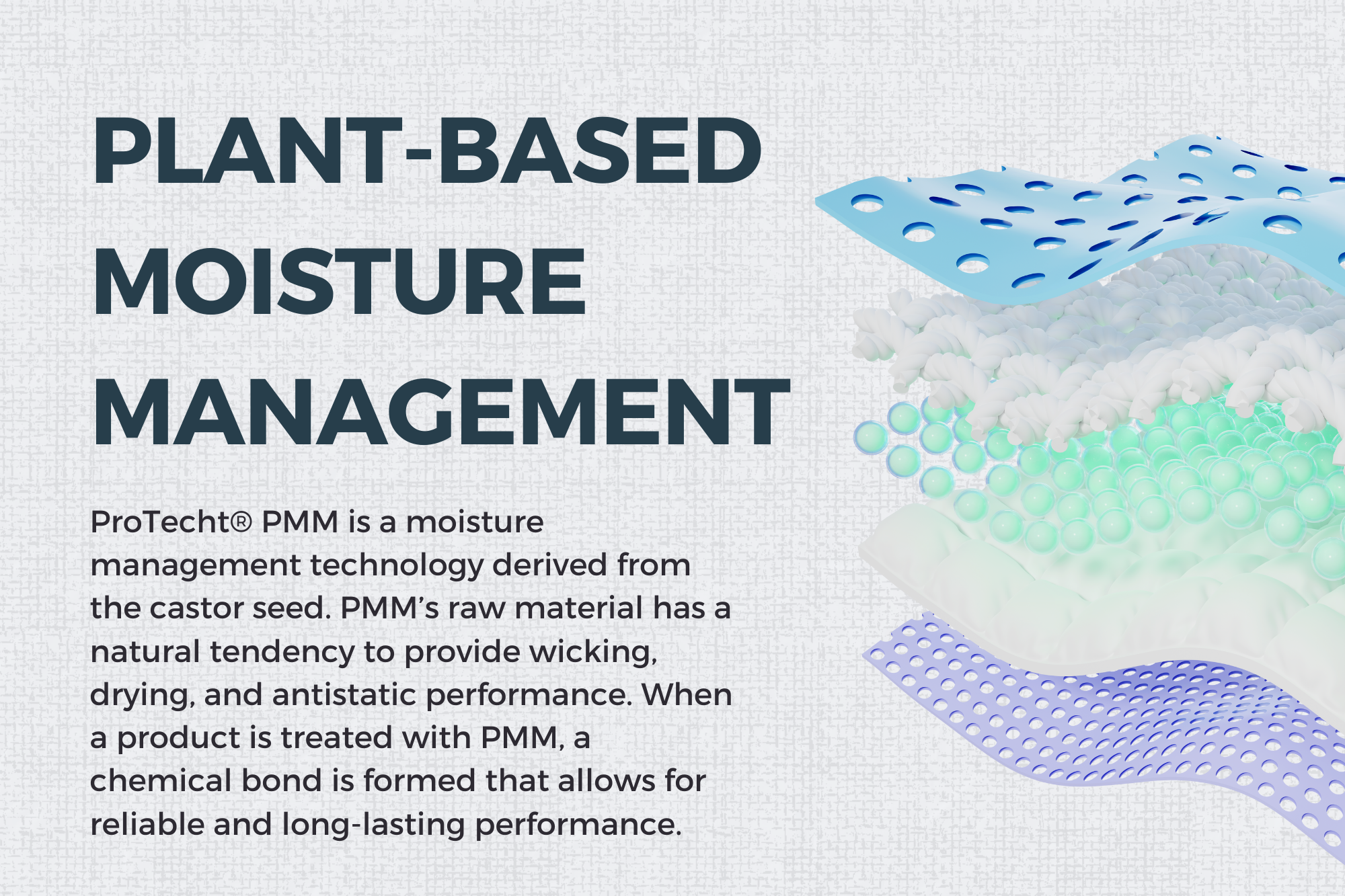

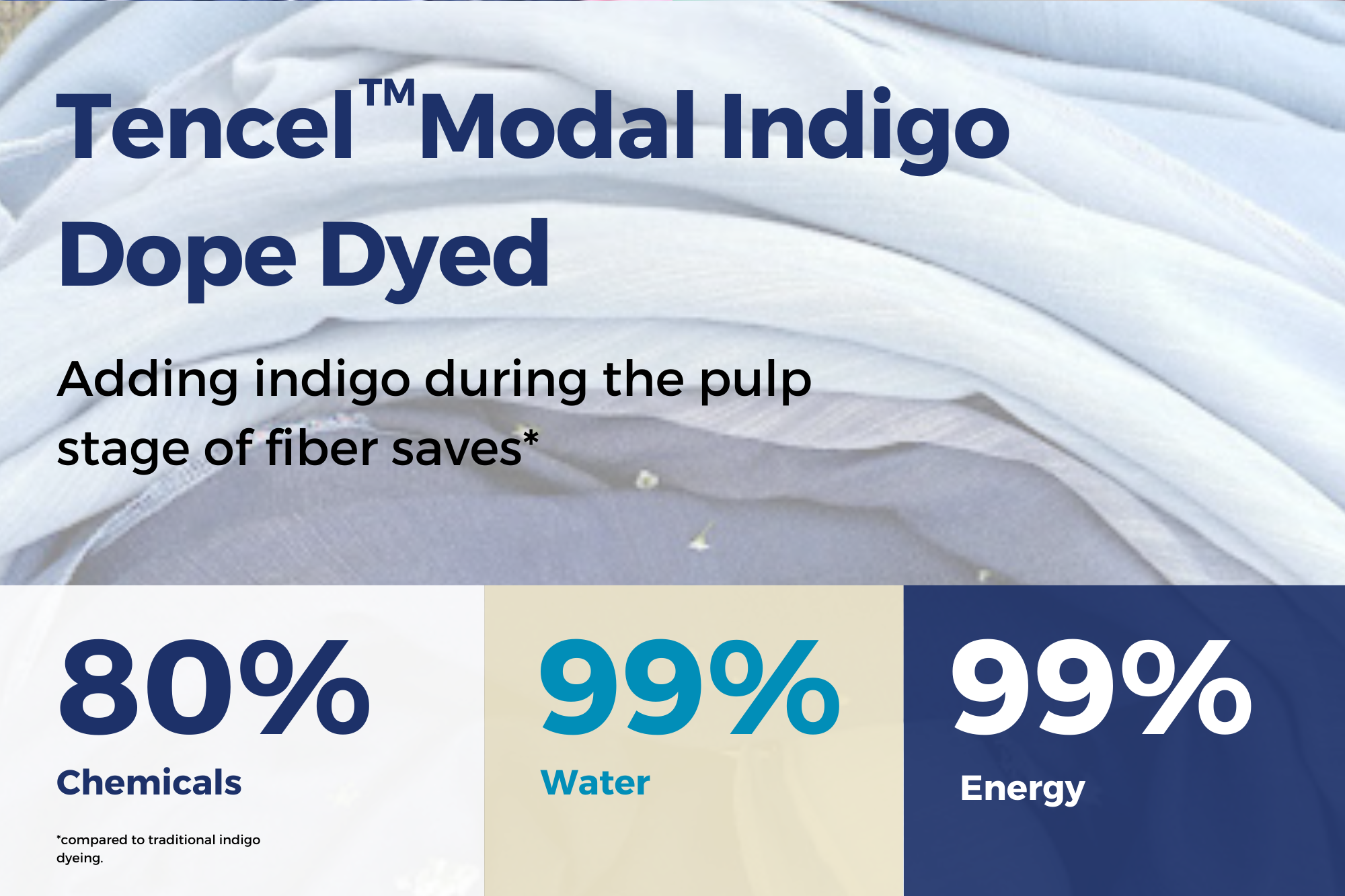

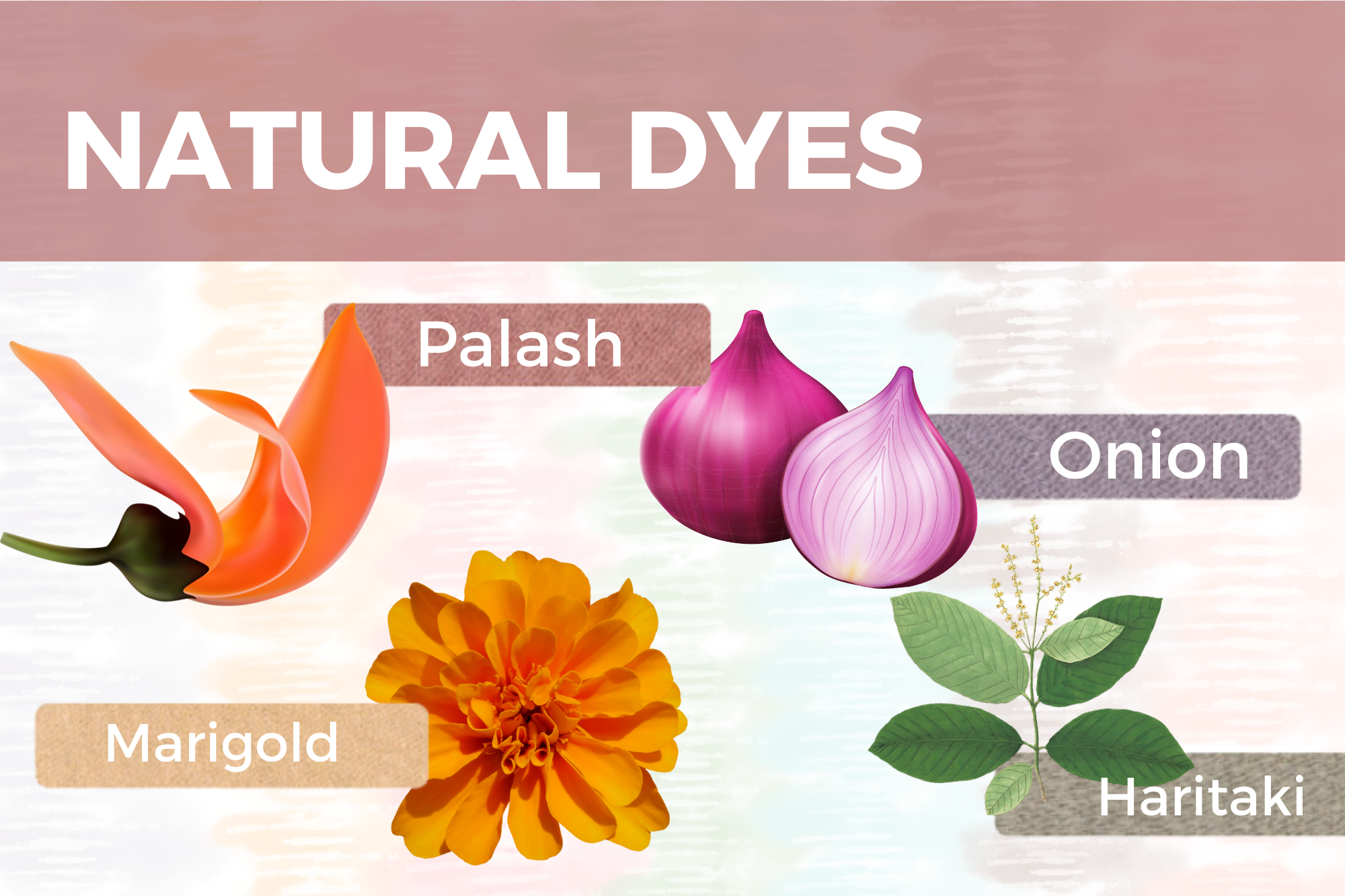

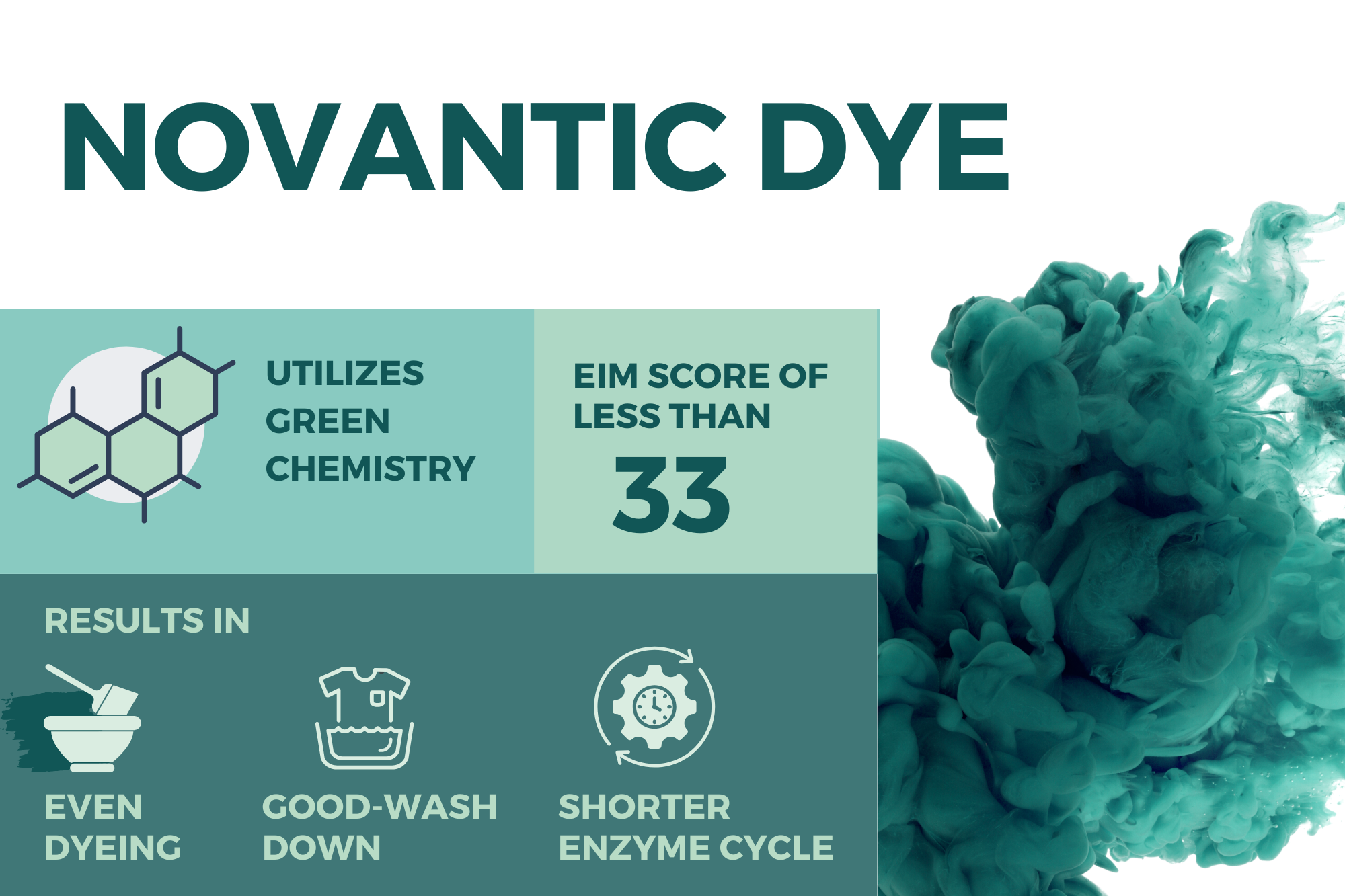

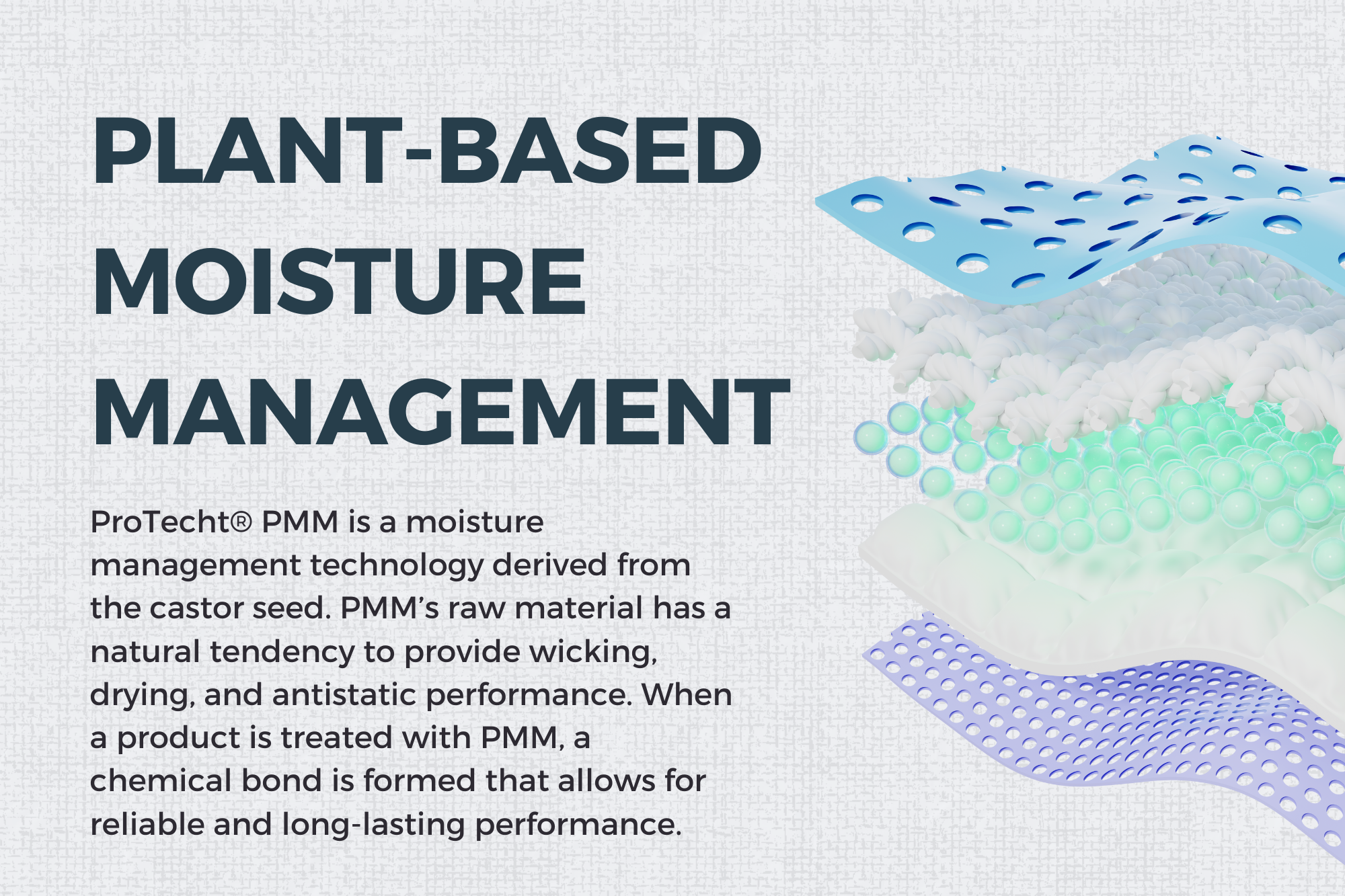

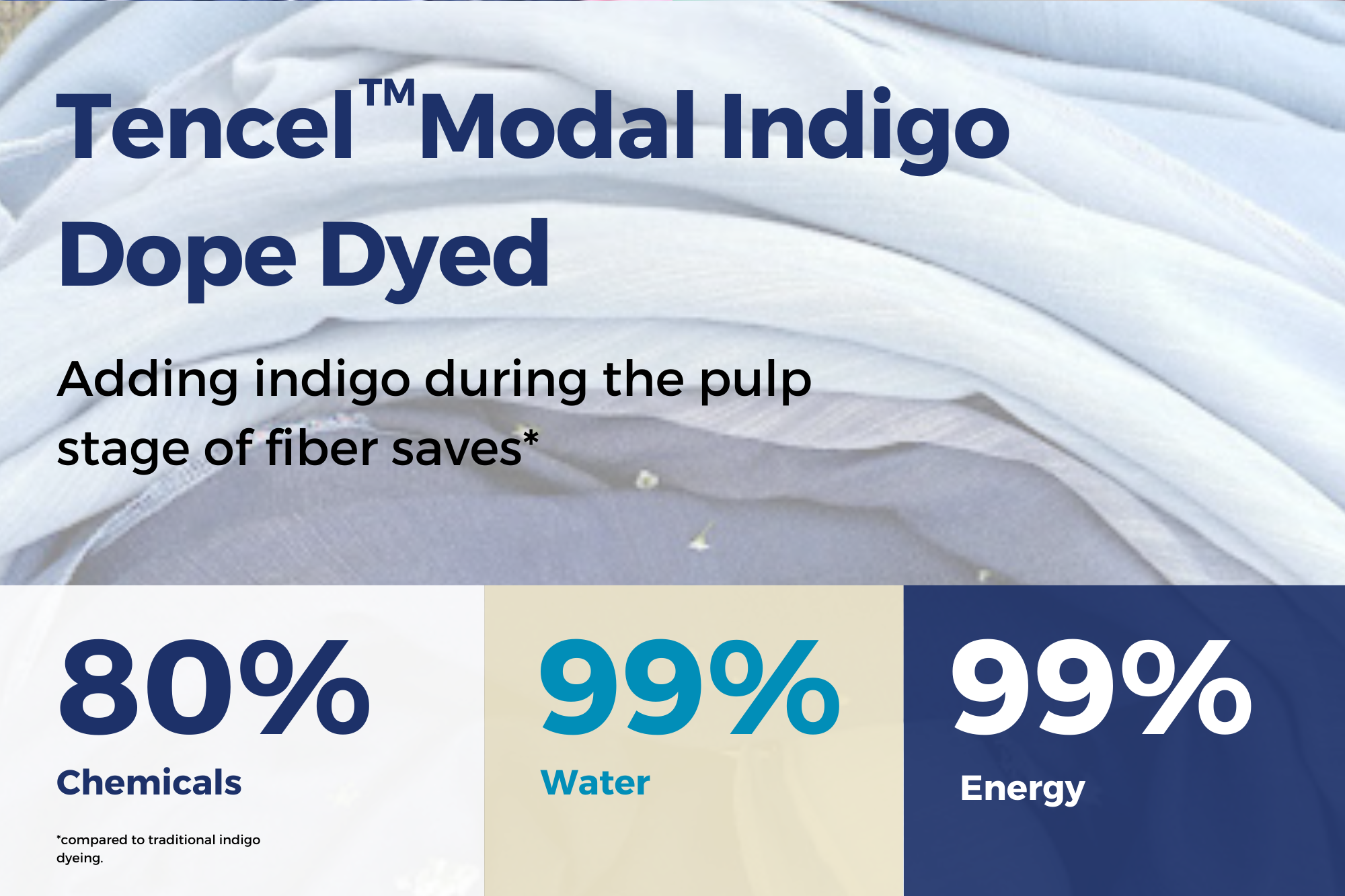

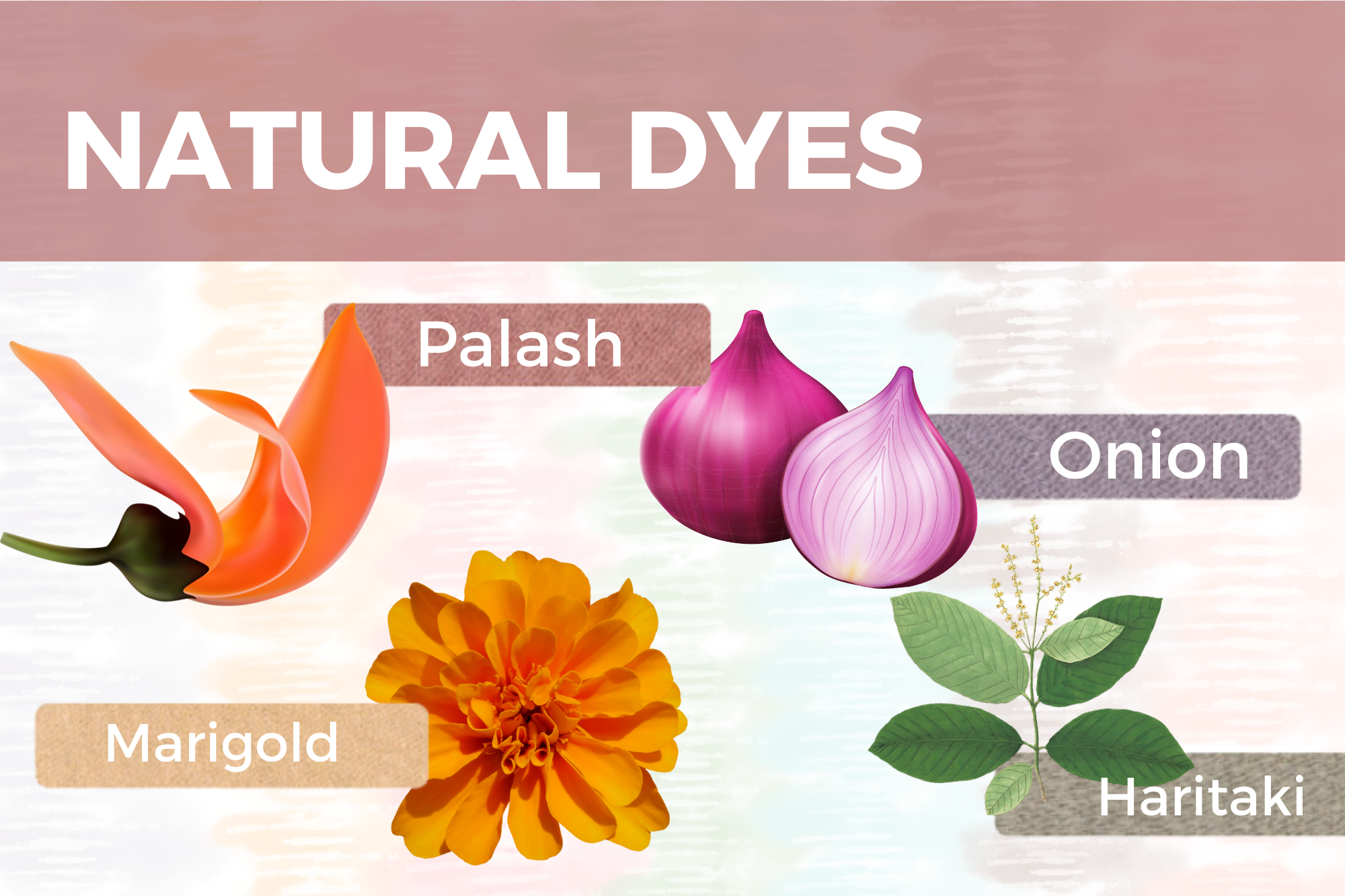

Alternative Dyes & Chemicals:

Our procedures for handling chemicals ensure the minimization of the use of hazardous chemicals and prevent them from entering our manufacturing process.

We are constantly researching and finding ways to reduce and substitute chemical use in washing.

Proper Storage and Handling:

Our Chemical Management Policy and Chemical Purchase Policy govern our effective chemical management. Our processes are in alignment with ZDHC TIG (Technical Industry Guidelines).

Sustainably sourced materials:

Our material sourcing strategy prioritizes acquiring raw materials from partners within sustainable supply chains, specifically considering environmental and social factors. We continuously work on testing newer sustainable alternatives to conventional materials and actively market them to our customers.

Read more about how we created India’s first woven Cradle to Cradle Certified® Gold product.

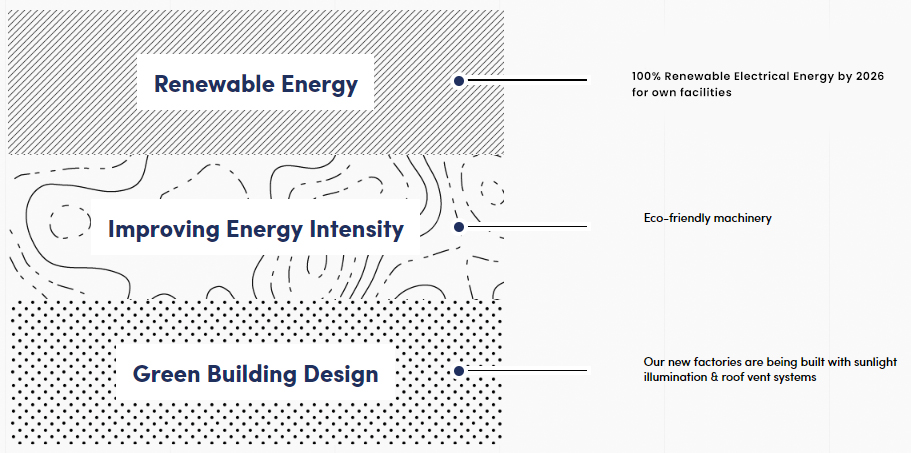

100% renewable electricity by 2026

Renewable Electricity:

We have set up solar power plants and windmills in Karnataka with total capacities of 92.5 MW.

These generate 70% of Shahi’s total electrical energy consumption. Know more about Shahi’s journey to 100% renewable energy.

Clean Energy:

In Shahi’s efforts to reduce carbon footprint, we have taken a bold step toward a greener and cleaner future by completely phasing coal out from our garmenting units.

50% carbon neutrality by 2026

Emissions:

Shahi is reducing carbon emissions by:

Energy Efficiency:

Our measures taken for reducing energy intensity include:

Train 100% of our supervisors by 2024

STITCH: Supervisors’ Transformation Into Change Holders

In 2016, Shahi partnered with Good Business Lab (GBL) to design a 6-month soft-skills program tailored for line-level supervisors, which encompasses sessions on topics ranging from problem-solving and coaching to gender sensitivity and improving workplace culture.

GBL’s research shows that STITCH enhances supervisors’ stock of soft skills, reduces turnover, and increases the workers’ productivity in their lines, thus raising incomes and the probability of receiving incentive bonuses. Know more about STITCH.

PULSE: Promoting Upcoming Leadership at Shahi Exports

An 8-month immersive curriculum in leadership through personal and interpersonal growth. This program equips participants to embody Shahi’s vision and cultivate a positive and productive work environment.

Enroll 500 leaders in eight months of leadership course training under PULSE by 2025

Implement in all units of the Knits Division and Men, Bottoms, and Denim Division by 2025

Captain Program:

An upskilling program designed to elevate the work environment by promoting holistic skills in candidates chosen to become Captains. Candidates undergo comprehensive training to manage sewing lines.

Gap Inc. P.A.C.E.:

A comprehensive life skills training crafted for female garment workers, encompassing communication, time, stress management, legal awareness, execution excellence, and more.

With the Good Business Lab, we studied the business impact and found a positive return on investment, which has created a powerful business case for extending the program to every worker:

GBL’s research shows P.A.C.E. beneficiaries are:

– 20% more productive

– Likely to get promoted up to three times quicker

– More likely to enroll in further skill development courses

– Increased confidence and self-esteem

– Stronger communication skills

– Greater financial awareness and goal-setting

– More likely to save for their children’s education

– More likely to take advantage of state-sponsored pension and health schemes

Train 90,000 women in Gap Inc. P.A.C.E. by 2024

Skill 65,000 women by 2024

Training Centers

States

Skills for Employment:

Skill Development is a potent instrument for personal and societal advancement. As a project implementation partner since 2013 for the Government of India, we offer training programs to underprivileged youth and women.

Social and Labor Convergence Projects (SLCP):

Since 2019, we have proactively participated in the Social and Labor Convergence Projects (SLCP).This has mitigated audit fatigue by saving 1,728 hours while establishing a uniform assessment framework for our factories.

Read more about SLCP here.

Cover 100% of our factories by 2024

Empowering Worker Voice:

Worker voice is indispensable at Shahi. The key drivers of effective worker voice are

Building our ability to listen through a variety of channels and enabling workers to transparently utilize channels and witness the journey that their participation takes.

Achieve 100% accessibility by FY 2024

We leveraged the power of lean and low-tech solutions in collaboration with Good Business Lab (GBL) through their two-way, multilingual, and anonymous communication tool— Inache.

Our pilot with the tool showed a:

Reduction in Absenteeism

Increase in Productivity

Workers have access to Inache

Worker satisfaction rate

Train 100% of our workforce in the first round of BSafe by 2025

In FY 2022, we launched BSafe, a two-hour per-worker per-month participatory awareness program developed in collaboration with A&F as a knowledge partner and training partner Kshitij, an NGO. The Garment Labor Union vetted these modules.

This initiative empowers employees by fostering a deeper understanding of different forms of harassment and our 6-pillars of redressal and remediation. This subsequently

– Enhanced their capacity to understand various grievance redressal mechanisms

– Encouraged them to use the grievance redressal mechanism effectively

– Increased their awareness about gender and gender-based violence in the workplace

– Enhanced their awareness about mental health, suicide prevention and awareness, and cybercrime and its prevention

Prioritizing Employee Safety at the Workplace:

Our organization has a well-defined occupational health and safety management (OHSM) system per the Factories Act of 1948. The OHSMS is based on the standards prescribed by the International Labour Organization. Safety and Well-being Officers at each unit ensure these standards are upheld, and all safety measures are followed without compromise.

We have established our goals and are dedicated to:

– Complying with all relevant safety laws, regulations, and requirements

– Implementing process safety and management strategies, including safety committees, audits, risk assessments, and documenting safety-related data

– Creating a workplace free from injuries by fostering strong employee engagement

Training and Awareness:

We conduct extensive safety training, health camps, and awareness sessions to empower our workforce with the knowledge necessary to minimize risks. We reduce the likelihood of workplace fatalities by raising consciousness among our employees.

Employee Health:

Within all our facilities, we have established fully equipped medical centers with skilled medical teams comprising nurses and doctors to address primary injuries and provide direct medical care. Furthermore, our employees and workers benefit from coverage under the Employees’ State Insurance (ESI). We organize several camps such as

– Anemia Detection Camps

– Audiometry Camps

– Employee State Insurance Corporation (ESIC) Camp,

– Eye Health

Post-Natal Care, and Creche Facilities:

We understand the challenges associated with balancing professional responsibilities and parenting duties. Our crèche care has been crafted to offer a secure and nurturing environment for the children of our employees aged below six years. We ensure that the crèche meets the highest hygiene and child development standards.

We strive to reduce waste generation through careful planning and innovation by optimizing our production processes, promoting recycling, and fostering circularity.

Our Waste management policy ensures our legal compliance with respect to waste generation, storage, and disposal. It helps us improve our waste management processes, avoid unnecessary use of raw materials to minimize waste generation, and reduce hazardous waste within our premises. Our teams are trained in effective waste management practices.

In our mills and garmenting units, two distinct categories of waste are generated: hazardous and non-hazardous.

All hazardous waste is directed to an SPCB-authorized recycler or disposer. Non-hazardous waste is also sent to approved vendors.

Reducing Waste:

| Environmental Area | Goal | Target Year | FY 2021 Performance | Baseline Year Performance |

|---|---|---|---|---|

| Energy Baseline year (2018-19) | To have 100% renewable electricity | FY 2026 | 68% | 47% |

| To have 50% energy consumption from carbon-neutral sources | FY 2026 | 35% | 31% |

At Shahi, we recognize the significance of energy's dire impact on climate change. Investing in Green Building principles minimizes our energy consumption significantly in the long run. Green Building Design.

| Environmental Area | Goal | Target Year | FY 2021 Performance | Baseline Year Performance |

|---|---|---|---|---|

| Water and Wastewater Baseline year (2021-22) | To have 85% recycled water used for industrial purposes in garment units | FY 2024 | 80% | 2021-22 is the baseline year |

| To have 75% recycled water used for industrial purposes in textile mills | FY 2024 | 80% | 2021-22 is the baseline year |

Read more on our water efficiency in our Denim Operations.

A strong focus on sustainable material sourcing has enabled Shahi to achieve (FY 2021)

Read more about how we created India’s first woven Cradle to Cradle Certified® Gold product.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

Sr. GM – Operations

Shahi provides a great platform for learning and induces a sense of process ownership in all its employees.

![]()

Assistant GM – Human Resources

Shahi offers me complete autonomy in doing my job and achieving the targets set. The company has always appreciated my good performance and at the same time stood by me during tough times.

Chief Medical Officer

Shahi provides a great platform for learning and induces a sense of process ownership in all its employees.

Deputy GM – Organizational Development

Working with an organization which is founded by a lady and employing more than 70% females, is a real contribution to society — and I feel proud to be a part of it.

![]()

GM – Administration

Shahi has given me freedom to experiment with my creativity and has welcomed my new project ideas, which are now helping workers grow professionally and personally.

Budgeting

Savings

Responsible borrowing

Family discussion on finances

Links to local financial services