Shahi stands at the forefront of cutting-edge, vertically integrated textile operations. Our world-class state-of-the-art mills are dedicated to crafting woven and knitted fabrics, using premium-grade cotton and yarn sourced from our in-house spinning mill and reputable suppliers.

Approximately 80% of our textile mills' production capacity is channeled into 50+ of our state-of-the-art garment factories. Here, we produce apparel that reaches customers worldwide. The synergy between our in-house design, innovation, and laboratory teams allows for a seamless design-to-product process.

These aspects ensure unmatched visibility and an elevated quality standard throughout the production journey, from yarn to fashion. Shahi’s in-house design team and laboratory ensure seamless integration of our customers’ needs from fiber to final product.

Spinning, Knitting & Processing

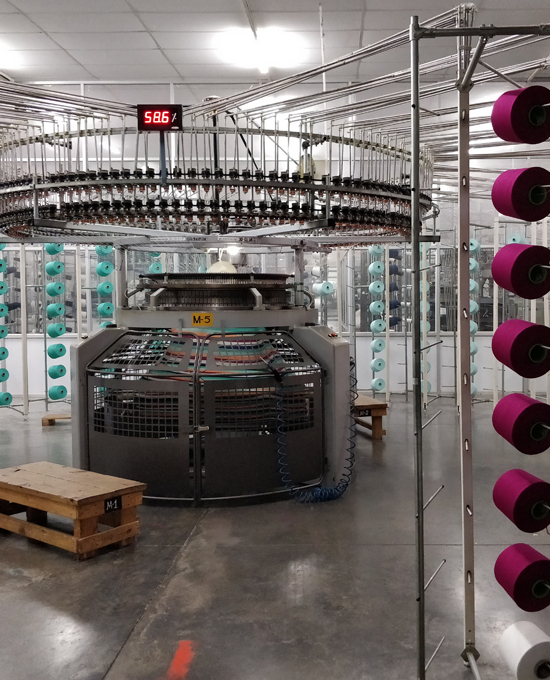

In 2012, Shahi set up a USD 130 million world-class, spinning-to-shipping facility located in Shimoga, Karnataka. The campus, which is spread over 250 acres, houses best-in-class technology from around the world for automated material flow and quality assurance. It delivers a wide range of knitted fabrics, including jersey, interlock, pique, lacoste, rib, French terry, jacquards, and auto stripes, in cotton and cotton blends, using low to high yarn counts.

We source cotton products with complete traceability and due diligence, ensuring ethical sourcing with global standards.

Spinning

Open-end Spinning

Knitting

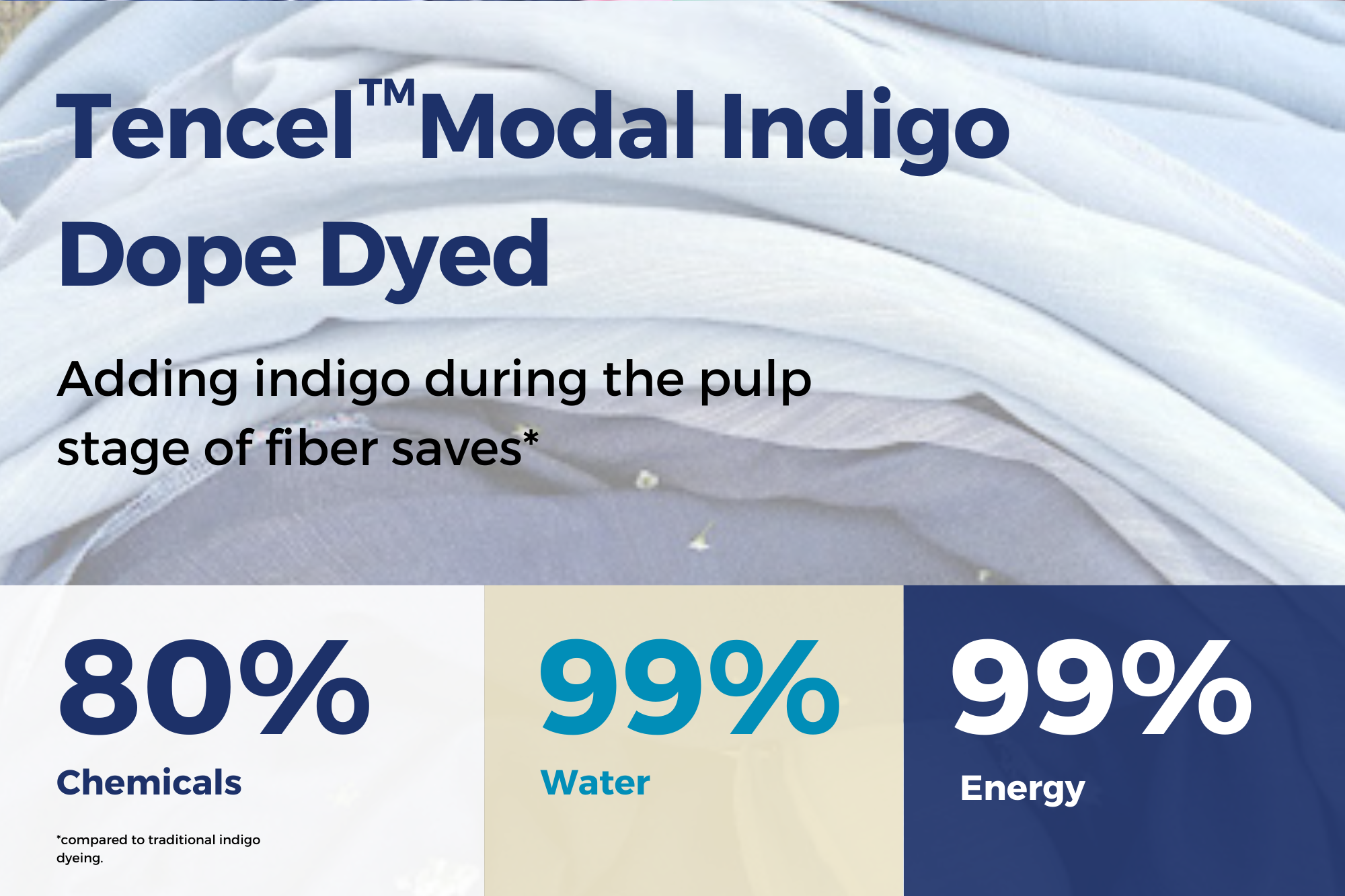

Yarn Dyeing

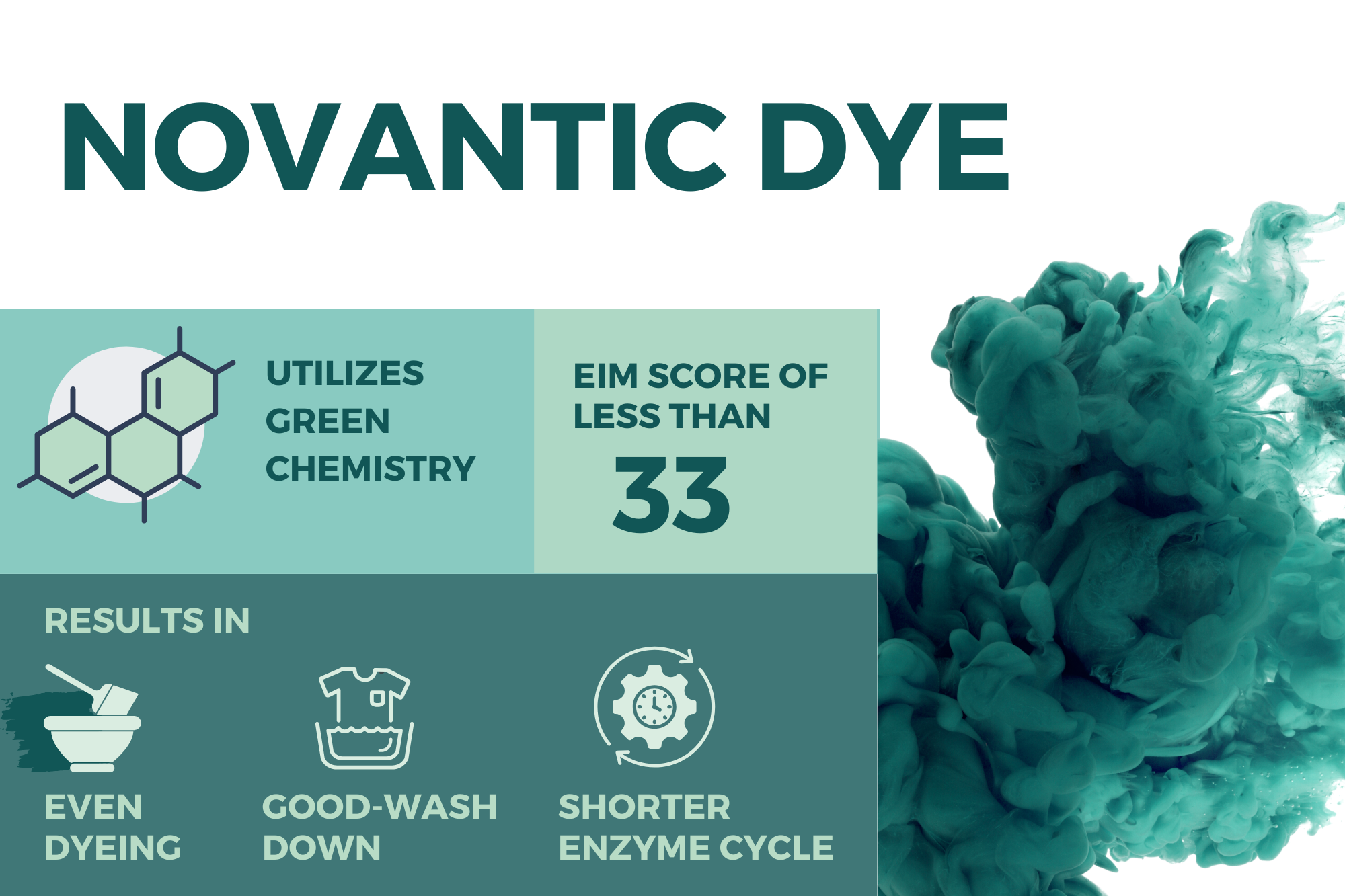

Fabric Dyeing

Weaving & Processing

In 1996, Shahi set up its first textile mill spread across 30,000 square meters, Sarla Fabrics Ltd., in Ghaziabad, Uttar Pradesh. Its Research and Development wing is certified by the Department of Scientific and Industrial Research. This enables a quick lead time for development and sampling.

In March 2018, Shahi launched its second wovens plant, spread across 900,000 square feet in Shimoga, Karnataka. The plant is designed to have a single-line layout from singeing to finishing, which optimizes material flow distance.

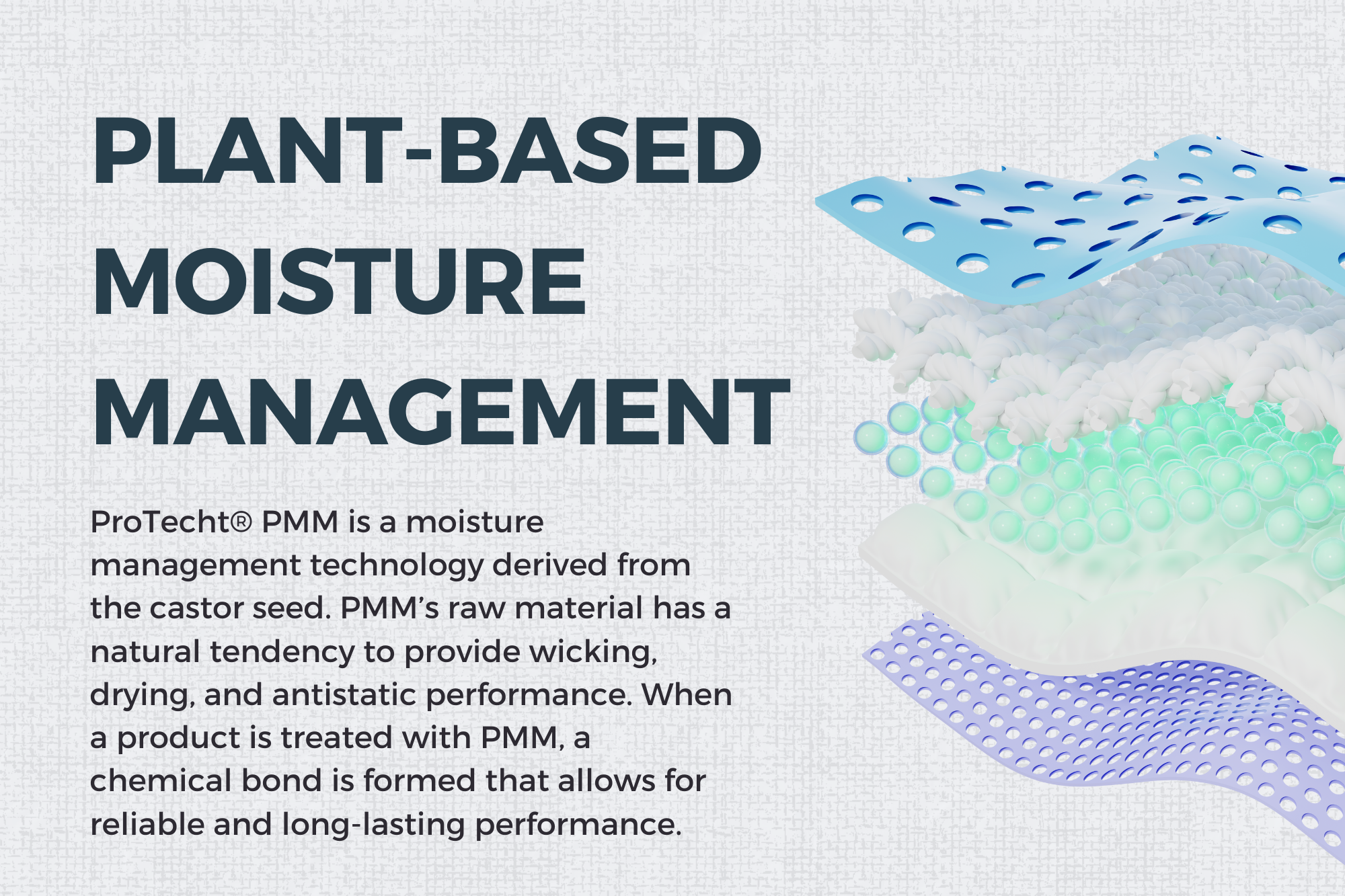

Our wovens facilities process cotton, rayon, linen fabric, and blends— from lightweight tops fabric to heavy bottoms fabric. These facilities can produce a variety of finishes, including standard finishes like mercerization, brushing, and peaching; and highly specialized proprietary finishes such as easy-care, wrinkle-free, and silky finish.

Weaving

Dyeing

Printing

Garmenting

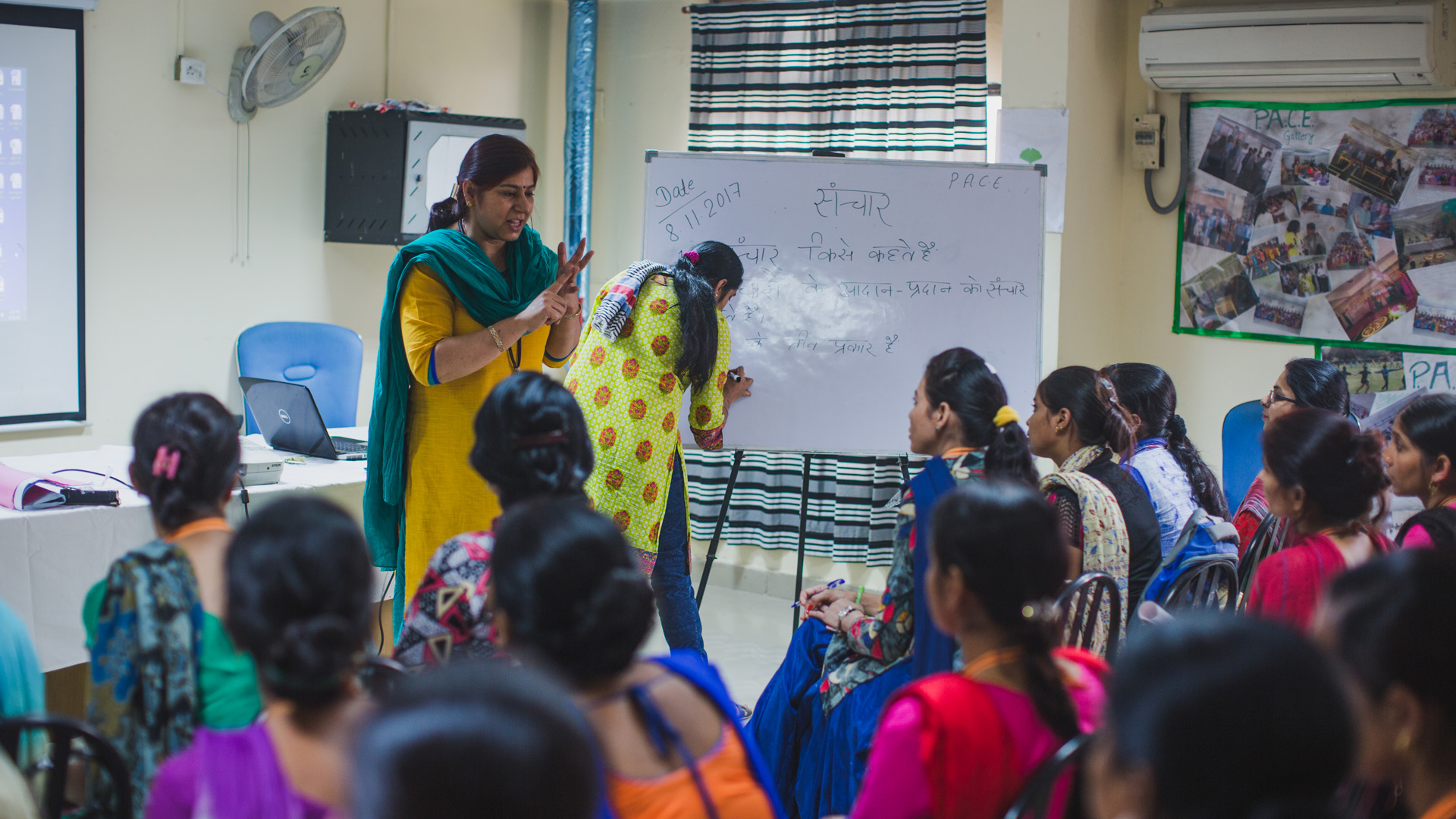

Shahi runs more than 50 cut-to-pack garment production units across 8 states in India, with one of the most extensive embroidery set-ups in Asia. Real-time quality control and precise execution of quality assessment procedures, in conjunction with lean manufacturing initiatives, help us create superior quality products consistently.

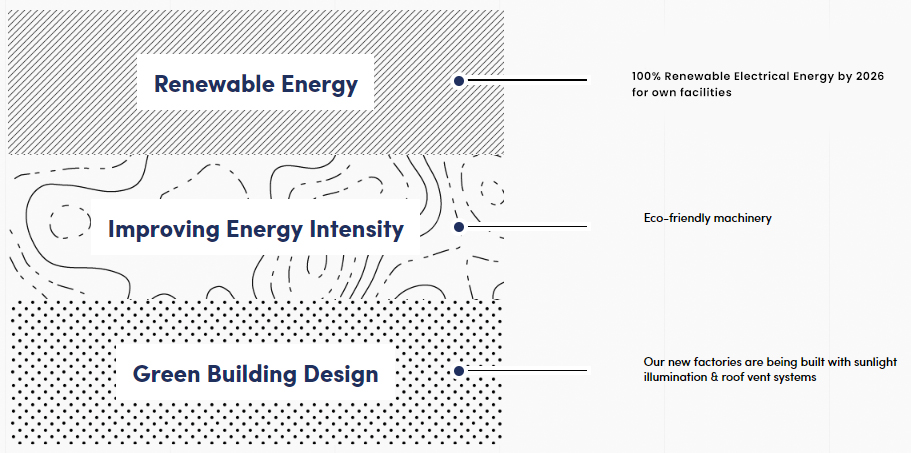

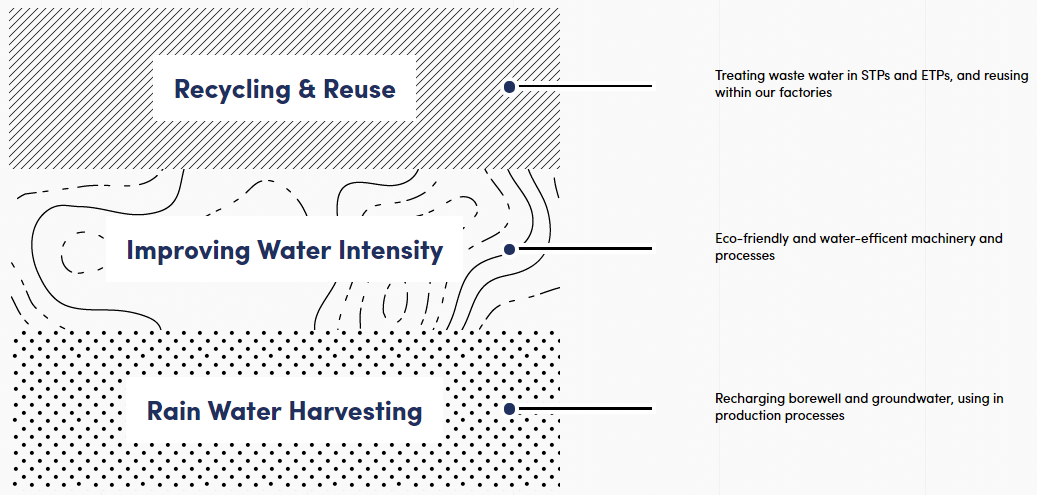

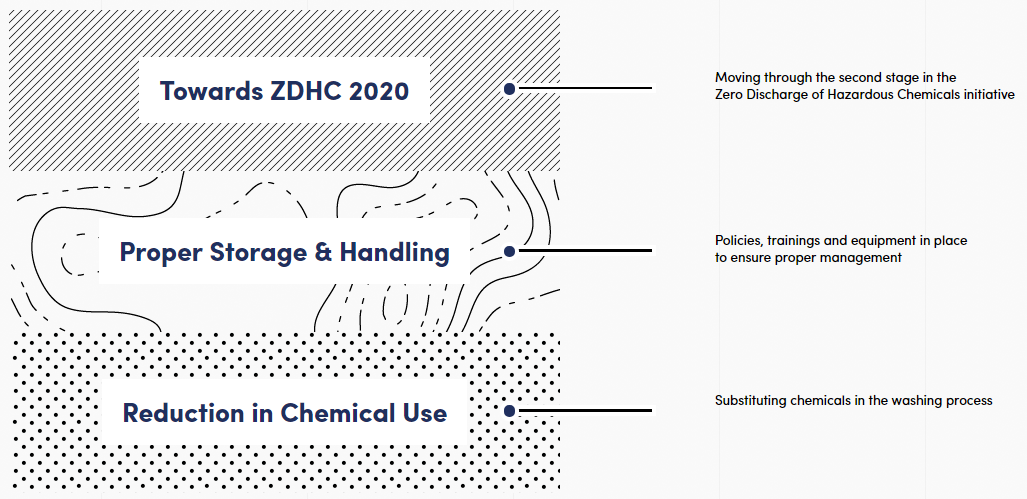

We have the latest wash expertise and can execute developments in technology from basic denim to innovative fabrics. We continuously invest in research and development to integrate the latest and most environment-friendly technology into our processes.

Our product capabilities include denim, twill bottoms, soft wovens, and knitwear.

Sewing

Embroidery

Embroidery machinery

Washing

Design

Our design and product development infrastructure comprises a dynamic team of over 90 skilled designers. Each of them specializes in various domains such as CAD (Computer-Aided Design), 3D draping, 3D sampling, textile innovation, and apparel design. Creating a digital twin of the same garment using 3D and VR technology speeds up the approval process. Augmented reality solutions eliminate the need to travel without compromising quality parameters, ensuring we remain ahead of the curve. Thus, conservation of resources and time is embedded into our design process.